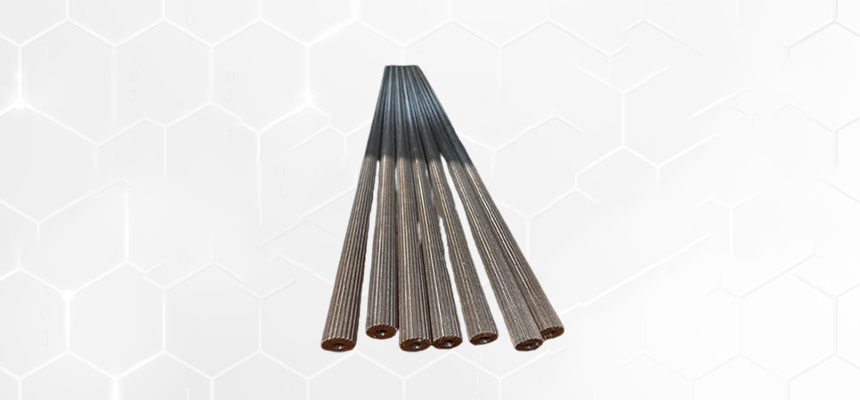

A spline shaft is a specialized type of mechanical component used in various industries, particularly in machinery and automotive applications. It plays a crucial role in transmitting torque while allowing for linear motion or rotation. Here is some information about spline shafts.

In summary, spline shafts are essential components used in a wide range of mechanical systems and applications to transmit torque while allowing for linear or rotational motion. Their design, material selection, and customization depend on the specific requirements of the application, and proper maintenance is essential to ensure their reliability and performance.